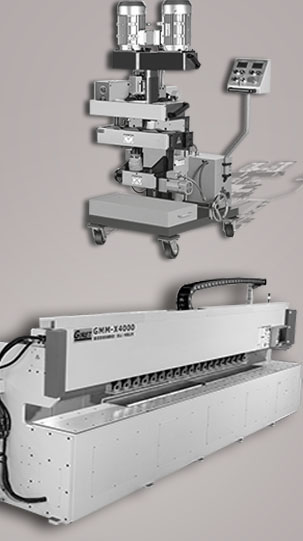

servo drive,Double spindle cutting machine, above bevel angle 0~90 degree, Under bevel angle 0~60 degree

GMM-X4000 CNC automatic table edge milling machine (HMI edge milling machine / touch screen edge milling machine) processing capacity:

Bevel angle

Upper spindle bevel angle: 0 ~ 85 ° (no step adjustment), supporting 90 degrees

Lower spindle bevel angle:0 ~ 60 ° (no step adjustment)

bevel width

Upper spindle 0 ~ 85 degrees bevel width:0~100mm

Upper spindle 90 degree step bevel width: 0~40mm

Lower spindle bevel width: 0~80mm

Feed speed:0 ~ 2000mm / min (according to material change)

Thickness plate:6 ~ 80mm (thicker can be customized)

Length plate:> 150mm (measured length, shorter can be proofed)

Processing travelled; 4000mm

Processing material: Carbon steel, stainless steel, aluminum alloy and other metal materials

Machining bevel style: V type / K type / Y type / X type / U type / L type / 0 degree trimming

Bevel angle accuracy: ± 0.5 degrees

Bevel straightness accuracy: ±0.5mm

Bevel width accuracy : ±0.5mm

Operation mode: HMI, human-computer interaction, touch screen control

GMMM-X4000 CNC edge milling machine (CNC bench type edge milling machine) features:

1. PLC system control, the system is more stable;

2. HMI human-computer interaction interface, touch screen operation, intelligent beveling machine, which can be operated by ordinary workers;

3. Safer operation: the control panel is low-voltage, and the normal operation is far away from the moving components;

4. There is no step adjustment for the angle of the uphill opening of 0 ~ 85 degrees, and there is no step adjustment for the angle of the downhill opening of 0 ~ 60 degrees;

5. The accuracy of groove angle shall reach ± 0.5 degrees;

6. The straightness of processing groove shall reach the accuracy of ± 0.5mm;

7. Equipped with electrical cooling system;

8. Equipped with automatic chip removal system, cleaner;

9. More environmental protection, no cutting fluid and low noise;

10. Processing data can be stored and called at any time;

11. The human-computer interface diagram is intuitive;

12. Misoperation prevention system, automatic shielding beyond the limit;

13. The first construction starts the automatic operation groove program;

14. No manual calculation of processing data is required for groove processing, and the system automatically cuts in layers;

15. It supports two language versions, Chinese / English by default, and the language can be customized according to customer requirements;

16. Cold cutting, no oxidation deformation on the surface;

17. Real time monitoring of system input and output status;

18. Support remote rescue to make users feel more at ease;

19. The upper and lower groove angles are adjusted independently. The system allocates the spindle according to the customer's input data.

From: GIRET CNC edge milling machine and Beveling machine

Website: http://www.manific.com.cn

Our Factory Provides: CNC edge milling machine, HMI plate beveling machine, Table edge beveling machine, Plate bevelling machine, sheet bevelling machine, self-propelled bevelling machine, Stainless steel bevelling machine, Steel bevelling machine, Portable groove machine, handheld groove machine, portable groove machine, portable edge milling machine, Portable plate bevelling machine, Portable edge shearing machine, sheet beveling machine, plate welding grooves machine.